Circular Structures

4x4 Exterior NFC Sandwich Panel

4x4 Exterior NFC Sandwich Panel

Couldn't load pickup availability

4x4 Exterior Panel

Technical Data Sheet

General Description:

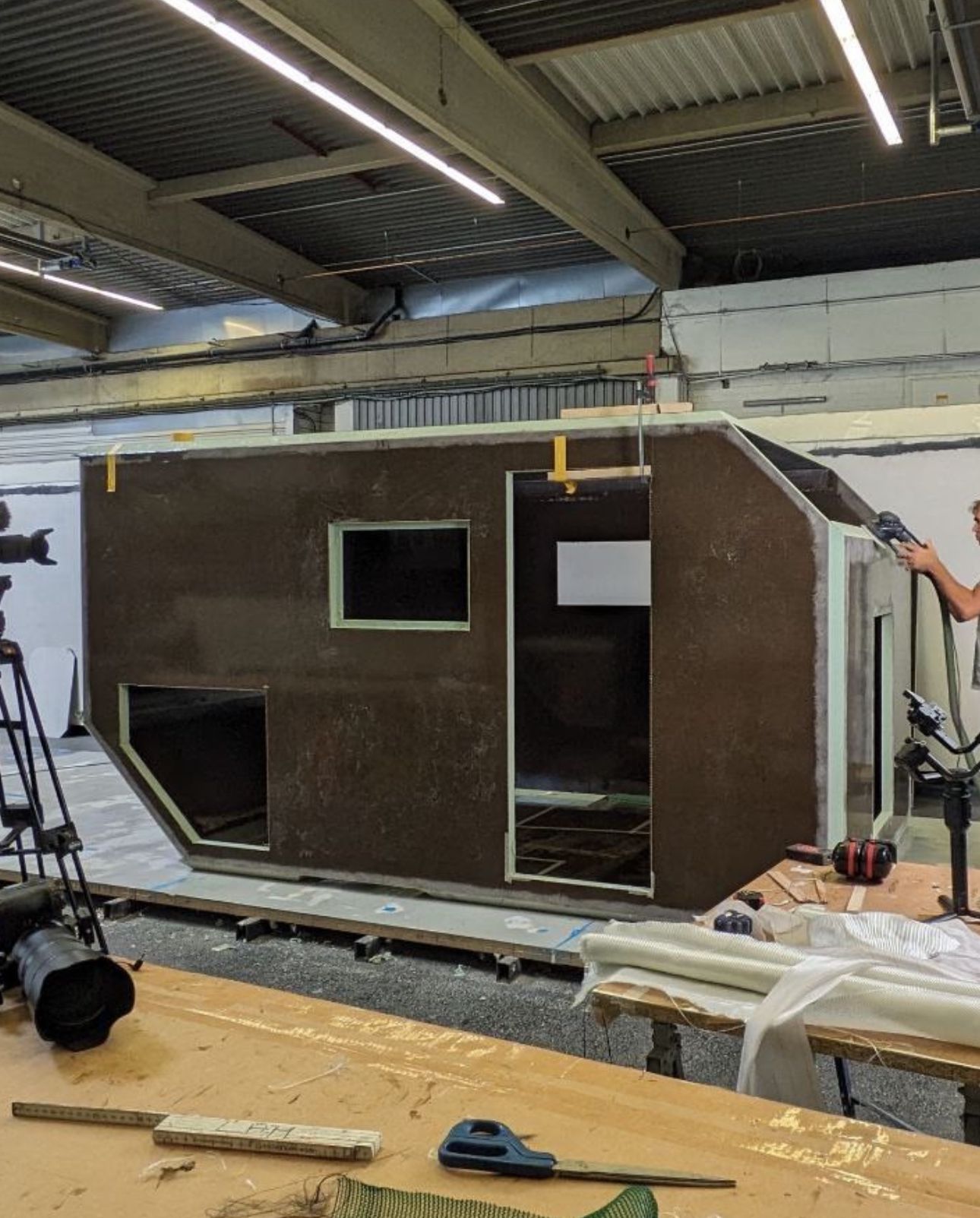

Our 4x4 Exterior Sandwich Panel is the ideal solution for off-road and expedition vehicles requiring robustness, lightweight construction, and sustainability. Featuring flax-fiber-reinforced skins and a core made from recycled PET foam, the panel combines cutting-edge material technology with eco-friendly design. It delivers exceptional mechanical properties, capable of withstanding the toughest conditions while meeting high aesthetic standards.

- Panel A: Sidewalls/Roof – Lightweight, strong, and insulating.

- Panel B: Floor – High durability and load resistance.

Technical Specifications:

| Property | Unit | Sidewall/Roof | Floor |

|---|---|---|---|

| Panel Thickness | mm | 43 (+/- 1 mm) | 43 (+/- 1 mm) |

| Panel Weight | kg/m² | < 7 | < 8.5 |

| Core Material | kg/m³ | 70 (ArmaPET GR70) | 100 (ArmaPET GR100) |

| Compressive Strength (ISO 844) | MPa | 0.75 | 1.5 |

| Compressive Modulus (ISO 844) | MPa | 40 | 70 |

| Shear Strength (ISO 1922) | MPa | 0.50 | 0.75 |

| Shear Modulus (ISO 1922) | MPa | 13 | 20 |

| Thermal Conductivity (at 23°C) | W/mK | 0.034 | 0.034 |

Material Properties of Face Sheets:

| Property | Value |

|---|---|

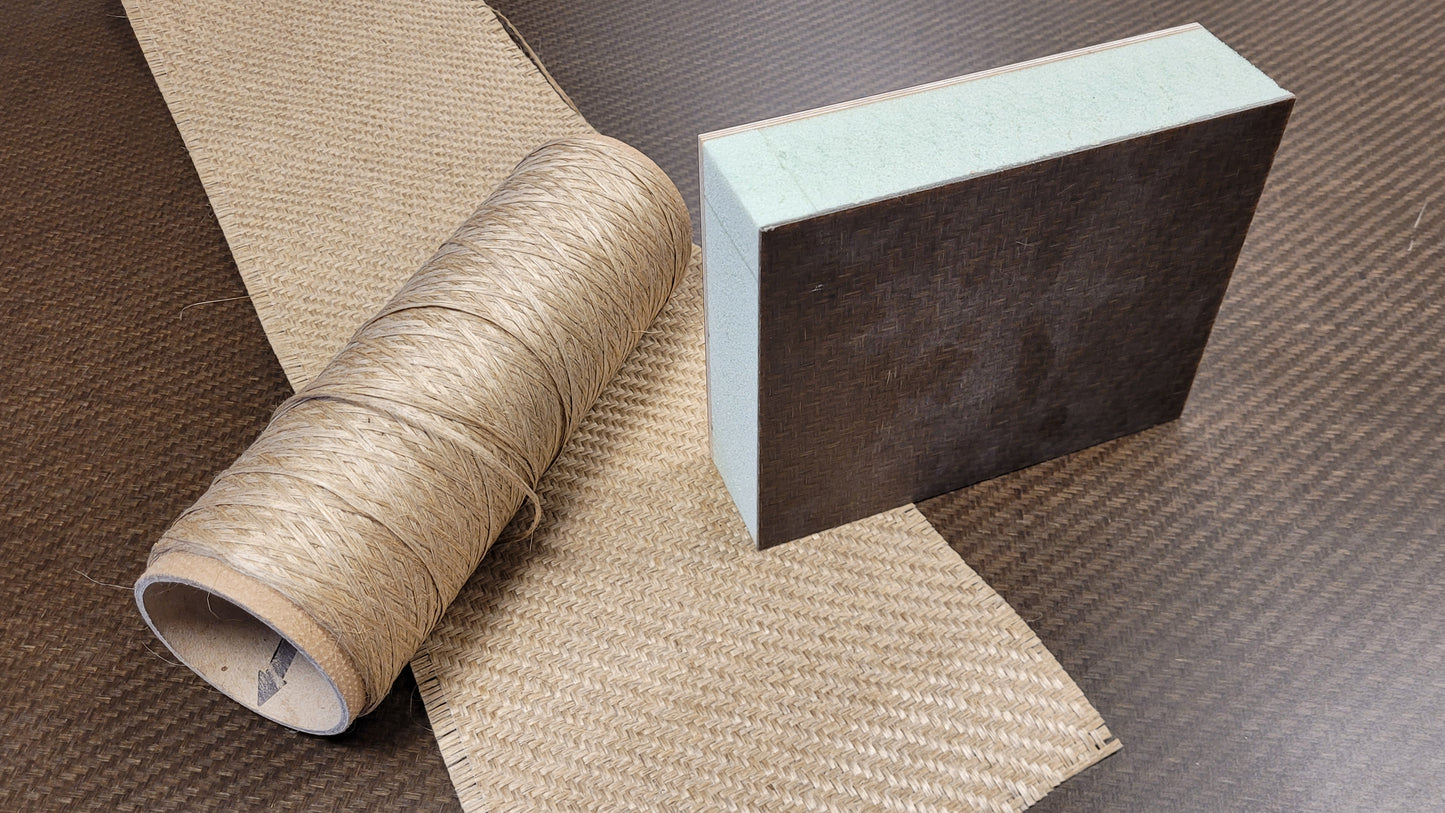

| Reinforcement Fibers/Orientation | GB-FT-0375/ +/-90 2/2 Twill 375 g/m² Flax fibers |

| Non-Crimp Flax Fibers | GB-FBX-0390/ +/-45 Biaxial 390 g/m² |

- Process: Panel pressing

- Weight: Approx. 1,600 g/m² (+/- 10%)

- Fiber/Matrix Ratio: Approx. 55%

- Matrix: 30% bio-based epoxy resin

- Thickness: 1 mm (+/- 0.15 mm)

- Dimensions: 6,000 x 2,440 mm (+/- 2%)

- Surface Finish: Primer film (paint-ready)

Advantages That Convince:

Lightweight Construction for Maximum Payload:

Weighing less than 7 kg/m², our 4x4 Exterior Panel is approximately 4 kg lighter than comparable products on the market. For a vehicle using 40 m² of these panels, this translates into a weight saving of 160 kg—the equivalent of two additional passengers or significantly enhanced equipment capacity.

Optimal Thermal Insulation:

With a thermal conductivity of just 0.034 W/mK, the panel provides excellent insulation. It keeps interiors comfortable under extreme conditions, whether in scorching deserts or icy regions.

Sustainability as a Standard:

The recycled PET core and bio-based flax-fiber face sheets set new benchmarks for eco-friendly materials. Our 4x4 Exterior Panel combines sustainability with outstanding performance—without compromises.

Superior Strength and Load Capacity:

The innovative panel structure offers exceptional load-bearing capacity and high resistance to mechanical stresses, making it ideal for use in demanding off-road and expedition environments.

Flexibility and Easy Processing:

The paint-ready finish saves time and effort during further processing. Panels can also be ordered in custom sizes to meet the specific requirements of any project.

For more detailed information request Technical Data Sheet (TDS)

Options (please get in touch with our team for a quote)

-Option: CNC Cut

-Option: Inserts for Floor Panel

-Option: Customize the core of your panel for your unique project needs. Our range provides options that serve multiple functions.

Delivery Terms:

Ex Works, Germany

Delivery Time:

Approx. 4-6 Weeks

Any Questions?

If your project requires specific materials or dimensions not listed, please feel free to contact our sales support. We are committed to enabling manufacturers to exploit the full benefits—both lightweight and sustainable—of Natural Fiber Composites.

Craft your ideal panel today and take the next step towards sustainable, high-performance building!

Share